Description

The Semi Paxy table is a positioning unit with CNC control unit which may be factory fitted onto any GEKA punching machine with a 500 mm or larger throat.

The assembly consists of:

- Mounting plate.

- Table assembly with “X” and “Y” axis driven by servo motors.

- B&R Power Panel 500 PC based 15” touch screen control

- Each axis “X” and “Y” has servo motors with built encoder for precise measurement.

- Electric cabinet

The work process is as follows:

- The position of the holes to be punched is programmed either in absolute or incremental dimensions.

- When the control is started up, the guide stops are positioned for first hole.

- The material to be punched is placed against guide stops and the punching pedal is activated, the ram then cycles.

- After the punch has returned to the pre-set clearance height, the table guide stops move to the next programmed position.

- Repeat this sequence until all holes are punched.

B&R PC based 15” touch screen control main features:

-

- B&R Power Panel 500

- Integrated keyboard

- Windows embedded operating system

- 15” colour touch screen WXGA resolution

- Compact Flash Memory.

- USB front port

- Ethernet port

- Easy and user friendly interface

- Programming is made through Line Pro software developed by Geka

- Importing of dxf/dstv files

- Network connectivity

- Remote assistance via the internet

- Run, design, jog, configuration and alarm modes

Electric cabinet

- Electric cabinet containing power and control equipment for the axis positioning and control of the machine

- Includes Allen-Bradley Guarmaster® safety relays

- Electric cabinet is mounted inside Hydracrop’s or Puma’s frame. If machine is retrofitted, the electric cabinet is mounted out of the machine’s frame.

- Standard input power is 400 V – 50 Hz – 3 phases. In case different input requirement is needed, let us know

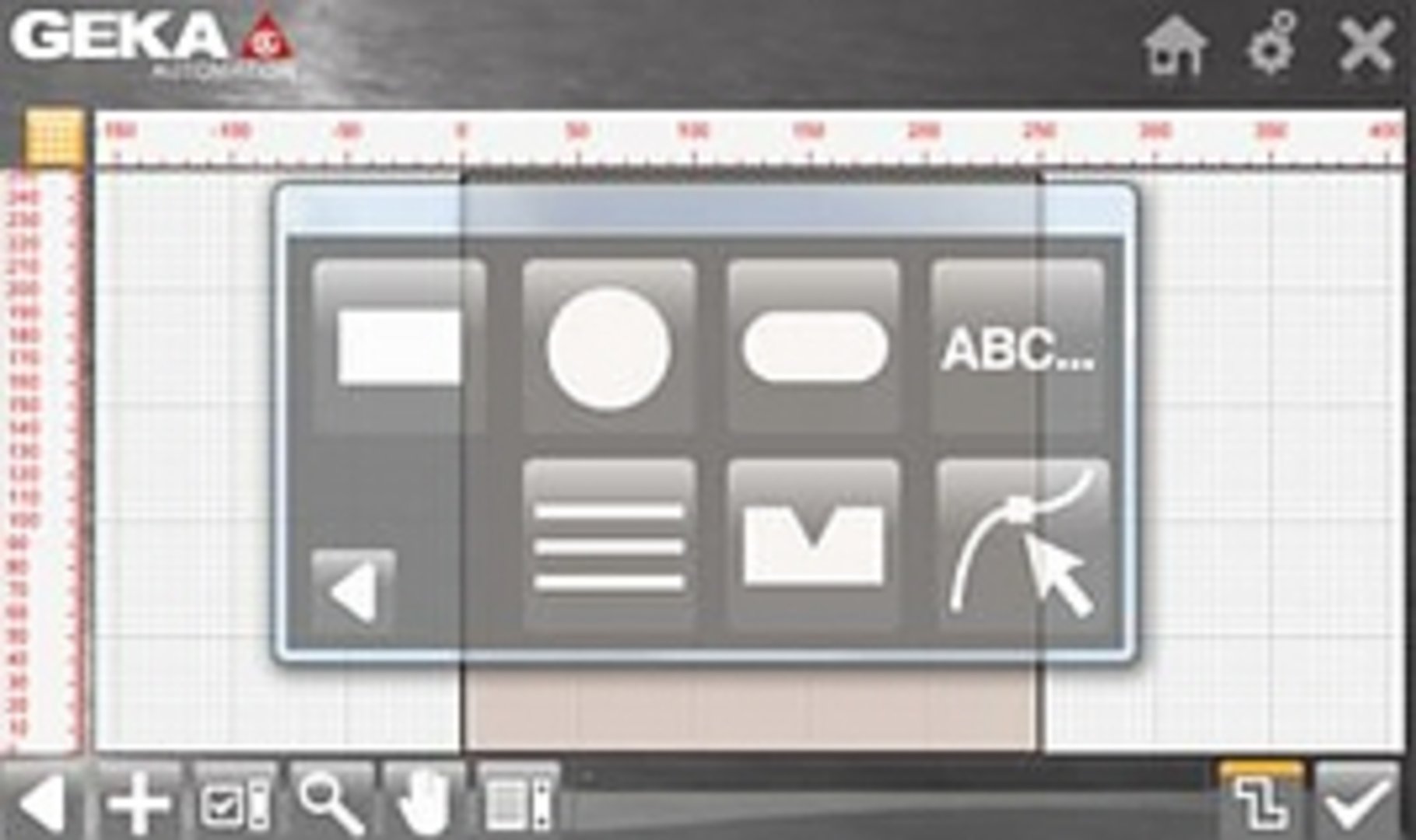

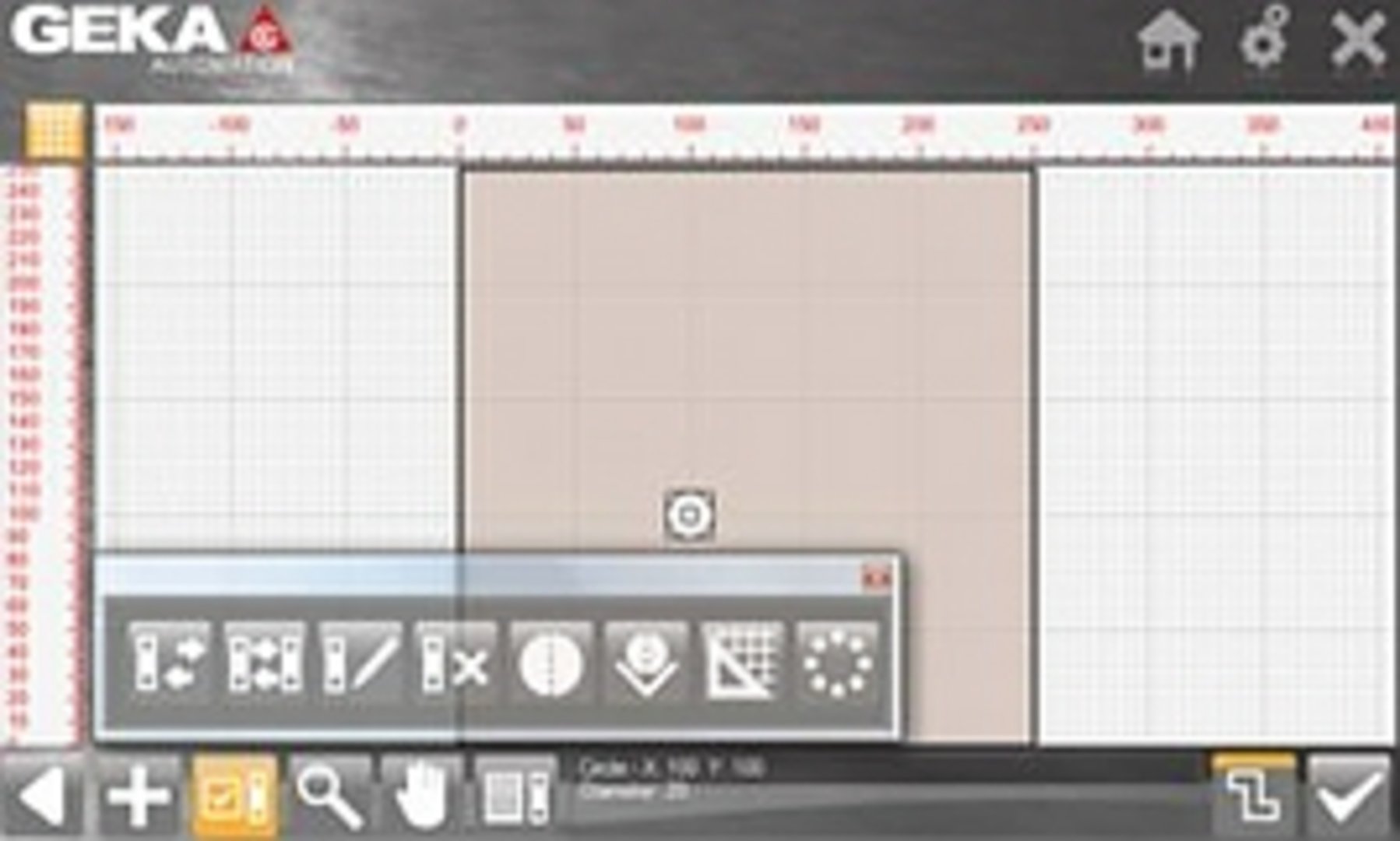

Line Pro main features:

- It is a visual and a very easy to use application with graphic representations.

- It shows the operator the image of the piece that is being designed.

- All the process of the part (from designing to manufacturing) can be done and controlled directly from the Positioning Control.

- Importing of dxf and dstv files available according to designing

specifications of the software. - It is easier to make changes on holes that have been already designed and the operator can easily identify any mistake on the part; as he is watching physically on the screen all the steps of the process of manufacturing of the part.

- Line Pro can be installed in a PC for later on sending the file via the network

or with a USB stick to the machine

-

Other X- and Y- ranges are also available, please ask for an offer.

Further information

Notice

Prices ex location, excluding VAT.

The General Terms and Conditions of Delivery of the Austrian Association of the Machine and Steel Construction Industry apply.

We only sell under retention of title, the goods remain our unrestricted property until they have been paid for in full.

Price changes and errors excepted.